Passenger comfort, operating economics and systems safety are all part of the appeal of Airbus’s new big twin

e-News® | May 25, 2015 : Airbus and Boeing are betting their futures on a new generation of long-range widebody twins with better fuel efficiency, lower operating costs and reduced noise and emissions compared with today’s two- and four-engine widebodies. The A350 is Airbus’s largest, longest-range, highest-flying and fastest-cruising twin. The A350-900, the first version now entering service with Qatar Airways and other carriers, is a larger aircraft than Boeing’s 787. With nine-abreast economy seating, the A350 can fly 315 passengers 7,750 nm at Mach 0.85. The 787-9 seats 280 and has a maximum range of 8,300 nm.

Both the A350 and 787 make extensive use of composites, have full three-axis digital flight controls and use the latest turbofan engines—Rolls-Royce Trent XWBs on the Airbus. But the A350 has a more conservative systems design than the 787, with fewer electrically powered systems. The Airbus has only two hydraulic systems, whereas the Boeing has three; its dual electrical systems provide the critical flight control redundancy.

The A350’s increased width enables it to retain the same 18-in.-wide economy-class seats with nine-abreast; the A330 can accommodate eight-abreast; Pressurization is increased to as much as 9.4 psi, resulting in cabin altitudes as low as 6,000 ft. at the aircraft’s maximum cruise altitude of 43,100 ft., to help reduce fatigue. The passenger windows are the largest yet in an Airbus, 2 in. wider than in the A330, providing more ambient light.

The strength and fatigue advantages of carbon fiber allowed designers to produce a higher-aspect-ratio wing for lower drag, and the A350 has the most sophisticated airfoil yet on a commercial Airbus. The wing has 31.9 deg. of quarter-chord sweep, 14-ft. scimitar-shaped winglets and spoilers that droop with flap extension to fully or partially seal the gap between the Fowler flaps and wing to reduce drag.

At Toulouse-Blagnac Airport, I belted into the left seat of the second A350-900, MSN002, with Airbus chief test pilot Peter Chandler in the right seat and Christian Norden on the jump seat as safety pilot. MSN002 is unrepresentatively heavy, loaded with test equipment and wiring. With two flight-test engineers and 11 passengers, zero fuel weight was 355,383 lb. Fuel load was 88,184 lb., for a ramp weight of 443,570 lb.—about 73% of maximum.

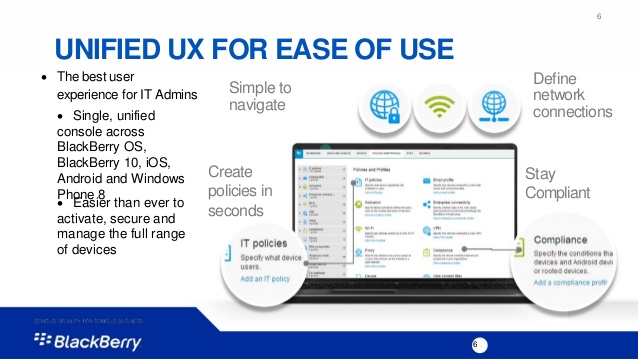

Strapping in, I was impressed with the quiet, dark cockpit design. If something does not require attention, it is not shown and not heard. Display color conventions are another strong point. Pull on a knob and you can select the data, shown in cyan. Push the knob and you have given authority to the computer, shown in magenta. Cyan also denotes a pilot action to be completed. Green signifies normal, active, completed action.

The A350 has the largest displays in an Airbus—six Thales 15-in. landscape flat panels. Outermost are the onboard information displays. In front of each pilot is the primary flight and navigation display (PFD/ND). The top center screen is the electronic centralized aircraft monitor (ECAM) with engine instruments, system display, mailbox and crew-alerting annunciations. The bottom center screen presents twin multi function displays, used for flight planning via a point-and-click interface.

Pre-start checks are impressively short. We plug in ground power, initialize the onboard information system (OIS), check ECAM and logbooks for discrepancies, run engine and auxiliary power unit (APU) fire-detection system checks with the press of a button, and start the Honeywell HGT1700 APU.

Using the OIS airport performance computer software, he entered Toulouse as the departure airport (elevation 489 ft.), Runway 14L, winds 10 kt. from 140 deg., outside air temperature (OAT) 19C and altimeter 1019 mb. Based on using Config 2 (drooped nose devices (DND) 16.7-deg./slats 18-deg./flaps 20-deg. deflection) and “Flex 50” thrust to reduce engine wear. The computed takeoff field length was 7,740 ft., with 9,843 ft. available. Flex 50 programs in an assumed OAT of 50C and reduces takeoff thrust to 84%. The OIS indicated we could have used Flex 60 to further reduce thrust and still departed safely.

The V1 takeoff decision speed was 132 kt. indicated airspeed (KIAS), rotation 133 kt. and V2 one-engine-inoperative takeoff safety speed 139 kt. On Airbus aircraft, V speeds are not automatically set on the PFD. Pilots manually set the numbers to help keep them in the loop. But the Honeywell flight management system (FMS) automatically bugged 137 KIAS as the minimum speed for retracting flaps to Config 1, 175 KIAS as minimum slat retraction speed and 196 KIAS as “green dot” best single-engine en route climb speed based on aircraft weight and altitude.

We repeated the process for the right engine then switched the start knob to the 12 o’clock “run” position after the start cycle was complete. Chandler secured the APU as it was no longer needed. Bleed air, fuel and electrical systems automatically reconfigured. He set Config 2 slats and flaps, we ran a control check, scanned the engine instruments and ECAM for normal indications and were ready to taxi.

The A350 is a large aircraft, with a 212.4-ft. wingspan, that will be operated at a variety of airports and in all weather conditions. Two features introduced on the A380 are carried over. The external and taxiing aid camera system (Etacs) uses nosewheel-well and vertical-fin cameras, along with guidance cues on screen, to help crews steer the aircraft so the main gear remains in the center of the taxiway or runway during ground maneuvering. Etacs also shows ground speed, helping the pilot gauge appropriate speed for straight sections or tight corners. The onboard airport navigation system (OANS) presents an interactive airport diagram on the navigation display when range is set to “zoom.” OANS shows aircraft position on the airport relative to named gates, ramps, runways and taxiways. When approaching a runway, the runway graphic flashes amber to warn of a potential incursion. No aural alerts are triggered.

When steering around tight corners, Etacs proved its value, as the main wheels are 95 ft. behind the pilots and 42.2 ft. apart. Using on-screen cues and camera imagery, I swung the nose wide of the corners to keep the center of the aircraft over the stripe. Chandler pointed out that Etacs showed the left engine was over the grass median while taxiing parallel to Runway 14L so we minimized power on that engine.

Cleared for takeoff on Runway 14L, we aligned the aircraft and advanced thrust to 25%. Engines stabilized, we pushed up the thrust levers to the flex/max-continuous detent. With thrust reduced to 70,728 lb. per engine, acceleration was moderate.

We cross-checked airspeed indications at 100 KIAS, committed to takeoff at V1 and rotated at 133 KIAS. Pitch response in direct control law was crisp, but well damped. The A350, like all other Airbus fly-by-wire (FBW) aircraft, has passive sidestick controls. Left and right sides are not electronically or mechanically interconnected, so do not provide visual or tactile feedback of cross-side or autopilot inputs.

Following PFD mode annunciations, thrust levers were pulled back to the climb detent at 1,990 ft. This engaged the autothrottles, but the levers did not move as the throttles are not back-driven. They remain fixed in position during autothrottle operation. Other PFD cues signaled when to accelerate, retract flaps to Config 1 (slats extended/inboard flaps 6 deg./outboard flaps 12 deg.) and retract all high-lift devices.

The aircraft is impressively easy to hand-fly. Normal flight control law so effectively maintains flightpath vector that only small, occasional stick inputs are needed to adjust pitch and bank angles to achieve speed, altitude and direction targets.

Leveling off at flight level (FL) 220 we disconnected the autothrottles for some basic maneuvering at 300 KIAS. Chandler says it is advisable to “match then mash,” meaning the throttles should be moved to match their position with actual engine output before “mashing” the autothrottle disconnect button. This prevents an uncomfortable thrust surge. This step would not be necessary if the throttle levers were back-driven by the autothrottles.

Rolling into 45-deg. bank turns, virtually no back pressure was needed on the sidestick to maintain altitude because of the flightpath stability function in the control laws. But, as the FBW system has an artificial spiral stability feature that tends to return the aircraft to a 33-deg. bank angle during steeper turns, it is necessary to hold lateral pressure on the sidestick to maintain 45 deg. Small thrust changes were needed to maintain 300 KIAS.

Next I leveled the wings, pitched 5 deg. nose down and advanced thrust to climb power, deliberately holding forward stick pressure to accelerate through the VMO maximum operating speed redline. As we accelerated past the limit, autothrottles automatically engaged and retarded thrust to decelerate the aircraft. Once we slowed below redline, autothrottles disengaged and engine thrust again responded to throttle position. This functionality is changed from the A380, Chandler says; the autothrottles automatically disengage when aircraft speed returns to normal flight envelope limits.

Other FBW flight control demonstrations included various normal-law low-speed protection modes, such as preventing pilots bugging too low an airspeed. The lowest that can be selected, VLS, provides an 18-23% margin over stalling angle of attack, depending on phase of flight. The crew can still hand-fly the aircraft slower than VLS, but the aircraft will not exceed the Vαprot “alpha floor” angle-of-attack protection limit if the sidestick is released. If the pilot deliberately flies slower, autothrottles automatically engage at alpha floor to prevent stall. If the crew continues to pull back on the sidestick causing even higher angles of attack, the FBW system will ease down the nose at Vαmax, a maximum allowable angle-of-attack that still provides a 5-deg. margin over the aerodynamic stall.

The Vαmax limiting feature has a significant safety benefit when executing a maximum performance escape maneuver. Assuming normal law is available, the best escape maneuver is to roll the aircraft in the appropriate direction, then pull the sidestick back to the stop and add thrust as necessary. The FBW system will respond by increasing G load to the maximum allowable and/or increasing angle of attack to Vαmax to extract maximum lift without risking a stall. Airbus cautions that pilots still must be adept at hand-flying the aircraft, even in alternate or direct law, in case the computer flight envelope protections are lost.

For landing, Chandler says the FMS generates a VAPP final approach speed target, based on the VLS lowest selectable speed, increased by at least 5 kt. and one-third of the headwind up to 15 kt., to provide a safe angle-of-attack margin in case of low-altitude windshear. Autopilot and autothrottles will maintain the target until the aircraft is over the runway threshold.

Most or all of these safety functions are lost in alternate or direct law, but the system still provides a conventional stall-warning bug on the PFD airspeed scale along with an aural warning to alert the crew of an impending stall.

Next we experienced the FBW system’s thrust-asymmetry protection. Down at 13,000 ft., Chandler lowered the landing gear, selected Config 2 and had me hand-fly the aircraft with autothrottles disconnected. He then bugged the speed at VLS+5 and we began a standard 3-deg. approach descent. Reaching about 12,500 ft., I initiated a simulated go-around by advancing the thrust levers and starting a climb. As we rotated nose up, at Chandler’s command I removed my feet from the rudder pedals and he snapped back the left throttle to idle.

The A350 is the most technology-laden Airbus I have flown, and quite a leap forward from the A330, though pilots will be able to use a common type rating with differences training. Arguably replacing the A380 as Airbus’s technology flagship, the A350 has a significant number of advances, including extensive use of composites; a wing with improved lift-to-drag characteristics; more fuel-efficient Trent XWB turbofans; a higher-voltage, lower-weight AC electrical system; and more integrated avionics.

The A350 boasts more systems redundancy than any previous Airbus twin and a host of safety features to help protect the aircraft and occupants from a raft of pilot errors. Overall, the A350-900 is a carefully crafted balance of passenger experience, safety features and operating efficiency.

In response, the aircraft lost no composure. It just gently yawed to the left with less than half off-center movement of the sideslip indicator. It also slowly rolled left a few degrees, resulting in a gradual heading divergence. Mild right rudder pressure and right sidestick input stabilized the aircraft and returned us to the target heading. A little rudder trim neutralized right-pedal pressure. As with the A380, it is possible, but not recommended, Chandler says, to keep your feet flat on the floor after an engine failure on takeoff without risking loss of control.

The final demonstration involved flying in direct law. Still in Config 2, landing gear was retracted and the primary flight control computers switched off. In direct law, I rolled the aircraft left and right, noting it was still quite stable because yaw and pitch damping are retained. A few rapid throttle movements to check thrust versus pitch coupling showed it was remarkably mild for an aircraft with such powerful engines under the wings. Very small stick inputs were needed to counter pitch changes. We did not change high-lift or speed-brake configuration to check for associated pitch-moment changes, but overall the aircraft appeared easy to fly in direct law.

With the flight control system restored to normal law operation, we returned to Toulouse for landing. Based upon a 415,000-lb. landing weight and using Config Full for landing (DNDs 25 deg./slats 27 deg./flaps 37.5 deg.), the FMS computed final approach speed at 140 KIAS, adding 5 kt. to the 135 KIAS lowest selectable landing speed, equivalent to VREF with appropriate margins. Even at max landing weight, VAPP would have been only in the mid-140s, reflecting the efficiency of the high-lift system.

Chandler says there are several autobrake modes, including runway overrun warning (ROW), runway overrun protection (ROP) and brake-to-vacate (BTV) introduced on the A380. ROW and ROP detect the landing runway by comparing the aircraft’s position and flightpath vector to an airport database in the FMS. They use aircraft weight, configuration and ground speed, along with runway condition and wind velocity entered by the crew, to determine if the aircraft can safely stop on the available runway remaining. ROW provides warnings before landing and ROP protects the aircraft after touchdown by applying maximum braking to stop on the remaining pavement

To program BTV, Chandler pulled up the airport diagram on the navigation display, selected Runway 14L and Taxiway M2 as the turnoff point. Then he activated BTV, noting we had 7,600 ft. available for stopping between the touchdown zone and taxiway. Symbols on the airport diagram indicated large margins between both the dry and wet runway stopping points using maximum braking, so we were assured of comfortable deceleration to Taxiway M2.

Electing to hand-fly the aircraft, I disconnected the autothrottles. As we changed high-lift configuration, extended the landing gear and made several thrust and speed adjustments, the FBW neutralized virtually all the associated pitch-moment transients, so few control inputs were needed to keep the aircraft on the intended flightpath.

Once we intercepted the Runway 14L instrument landing system glideslope, I merely adjusted aircraft attitude and speed to keep the PFD’s flightpath marker on a 3-deg. glidepath and followed the flight-director cross-pointer cues. The aircraft was quite stable on approach and responsive to the throttles. Speed changed perceptibly with slight variations in rate of descent, so it was necessary to pay close attention to thrust.

I started the flare at about 30 ft. and pulled back the thrust levers to idle. But the round-out was too rapid and we thumped down from 15 ft. Using moderate reverse thrust, I slowed to where the autobrake system gently began to decelerate the aircraft. We reached the 10 kt. target speed just prior to Taxiway M2, where we turned off.